Waste Vapor Evaporator

Waste Vapor Falling-Film Evaporator

For the plants with large quantity of circulating cooling water (near by the sea, lake and river), we recommend GNSJ series Evaporator with high-position cooling tower. For the plants without large quantity of circulating cooling water, we recommend LNSJ series Evaporator with condenser. The condenser achieve indirect heating exchange between cooling water and second generated vapor from evaporator, which not only keep the cooling circulating water clean without any smell, but also reduce the cooling water consumption. So this kind of the evaporator is especially for the plant which is unable to supply large quantity of cooling water.

Normal Model:

GNSJ-2500L、 3500L、5000L、6000L、7500L、10000L、15000L、20000L

LNSJ-2500L、3500L、5000L、6000L、7500L、10000L、15000L、20000L

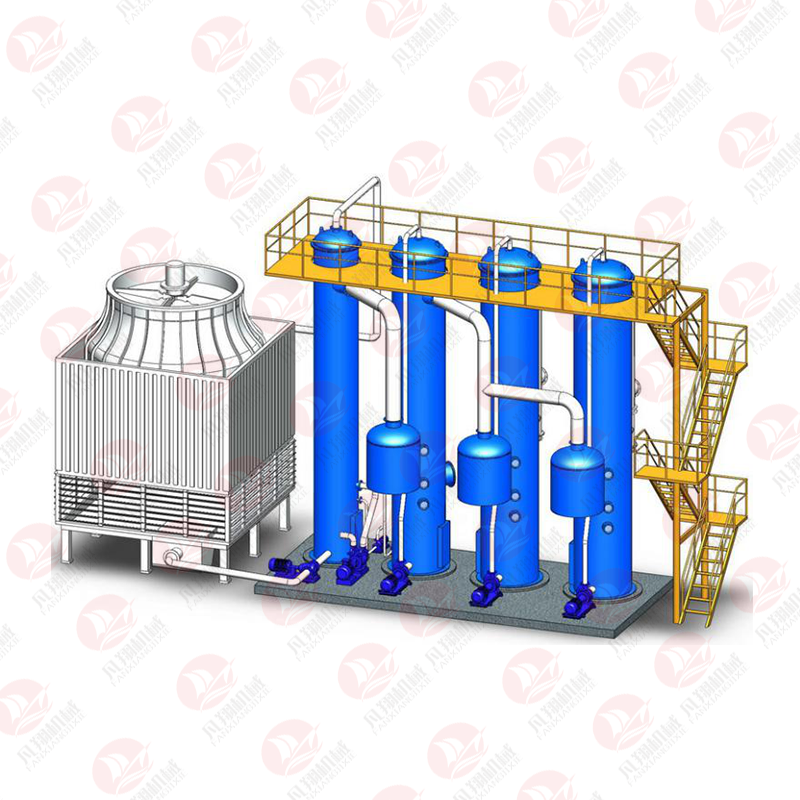

GNSJ Series Waste Vapor Falling-Film Evaporator

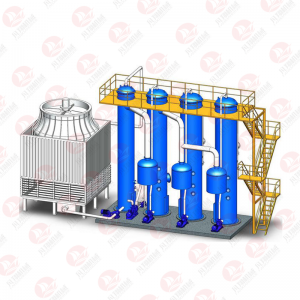

LNSJ Series Waste Vapor Falling-Film Evaporator

Waste Vapor Rising-Film Evaporator

The R & D team of our company keeps innovating, aiming at continuously improving product performance and providing customers with more efficient and advanced equipment. We have developed a new type of Evaporator based on the Waste Vapor Falling-Film Evaporator -- Waste Vapor Rising-Film Evaporator. For the plants with large quantity of circulating cooling water (near by the sea, lake and river), we recommend GNSJ series Evaporator with high-position cooling tower. For the plants without large quantity of circulating cooling water, we recommend LNSJ series Evaporator with condenser. The condenser achieve indirect heating exchange between cooling water and second generated vapor from evaporator, which not only keep the cooling circulating water clean without any smell, but also reduce the cooling water consumption. So this kind of the evaporator is especially for the plant which is unable to supply large quantity of cooling water.

The advantages of Waste Vapor Rising-Film Evaporator:

- Take full advantage of heating surface of heat exchange tube , better evaporation efficiency.

- The material is always filled with heat exchange tube, and its inner wall is not easy to coke during the heating process, no need of frequent cleaning.

Normal Model:

GNSJ-2500L、3500L、5000L、6000L、7500L、10000L 、15000L、20000L

LNSJ-2500L、3500L、5000L、6000L、7500L、10000L 、15000L、20000L

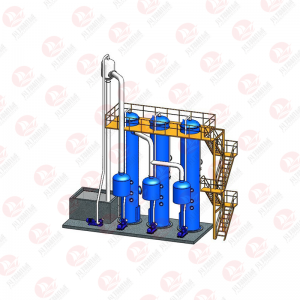

GNSJ Series Waste Vapor Rising-Film Evaporator

LNSJ Series Waste Vapor Rising-Film Evaporator

Installation collection

Double Effect Evaporation Concentration Devices

On the basis of the waste steam concentration device,combined with the form of steam vacuum concentration,it becomes a coherent system used for the production of enzymatic Fish Dissolved Pulp.The protein water first enters the I effect concentrator,where the waste steam generated by the cooker and dryer evaporates part of the water,

allowing the output concentration of the protein water to reach 16%.The 16%concentrated protein water is then pumped into the enzymatic hydrolysis tank for full enzymatic

hydrolysis,after which it enters the Il effect concentrator.The Il -effect concentrator uses fresh steam to rapidly evaporate water to reach a concentration of 55%,resulting in

the finished enzymatic Fish Dissolved Pulp."